1 The problem proposed

Technical unification provisions usually include “austenitic stainless steel vessels for the environment may cause intergranular corrosion, after welding should be solid solution or stabilization treatment”, put forward such a requirement, since the existence of its rationality. But even if the designers in the technical requirements of the drawings put forward this one, requiring manufacturers to stainless steel vessels (such as heat exchangers) after welding heat treatment, due to the actual heat treatment process parameters are difficult to control and some other unexpected difficulties, usually difficult to achieve the ideal requirements proposed by the designers, in fact, the vast majority of stainless steel equipment in service is used in the post-weld state.

This prompted us to think: intergranular corrosion is the most common form of corrosion of austenitic stainless steel, so what is the mechanism of intergranular corrosion? In what media environment will cause intergranular corrosion? What are the main methods to prevent and control intergranular corrosion? Austenitic stainless steel containers for the environment may cause intergranular corrosion after welding are not to heat treatment? In this paper, review the relevant standards, norms, monographs, combined with the actual production of personal views.

2 intergranular corrosion mechanism

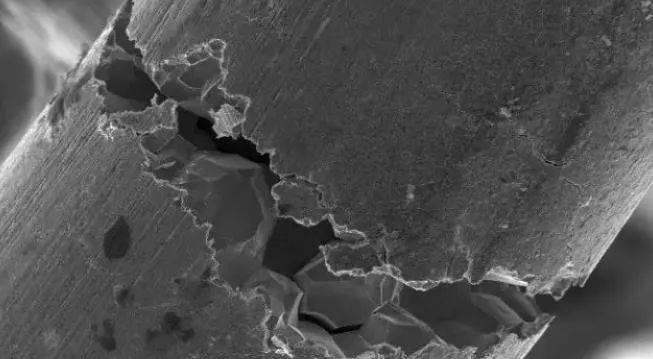

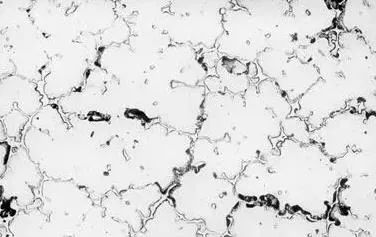

Intergranular corrosion is a common local corrosion, corrosion along the metal or alloy grain boundary or its adjacent areas of development, and grain corrosion is very slight, this corrosion is called intergranular corrosion, this corrosion between the grains of bonding greatly weakened. Severe intergranular corrosion, can make the metal lose strength and ductility, in the normal load cracking. Modern intergranular corrosion theory, the main chromium-poor theory and grain boundary impurities selective dissolution theory.

- 1 chromium-poor theory

Commonly used austenitic stainless steel, in oxidizing or weakly oxidizing medium, the reason for intergranular corrosion, mostly due to improper processing or use of heat caused by. The so-called improperly heated steel is heated or slowly cooled through 450 ~ 850 ℃ temperature zone, steel will be sensitive to intergranular corrosion. So this temperature is the use of austenitic stainless steel dangerous temperature. Stainless steel materials in the factory has been solid solution treatment, the so-called solution treatment is the steel heated to 1050 ~ 1150 ℃ after quenching, the purpose is to obtain a homogeneous solid solution. Austenitic steel contains a small amount of carbon, carbon in austenite solid solution degree is decreasing with the temperature. Such as 0Cr18Ni9Ti, at 1100 ℃, the solid solution degree of carbon is about 0. 2 %, at 500 ~ 700 ℃, about 0. 02 %. So by the solid solution treatment of steel, carbon is supersaturated.

When the steel is either heated or cooled through 450 ~ 850 ℃, carbon can be formed (Fe, Cr) 23C6 from the austenite precipitation and distribution in the grain boundaries. (Fe, Cr) 23C6 chromium content than the austenite matrix chromium content is much higher, its precipitation naturally consumed a large number of chromium near the grain boundary, and the consumption of chromium from the grain by diffusion in time to get replenished, because the diffusion of chromium is very slow, the result is that the chromium content near the grain boundary is lower than the limit of passivation must be (i.e. 12 % Cr), the formation of chromium-poor area, so the passivation is damaged, the region near the grain boundary The potential drops, while the grain itself remains passivated with a high potential, and the grain and the grain boundary form an active-passivated micro-electro-couple cell with a large cathode to small anode area ratio, which leads to corrosion of the grain boundary area.

- 2 grain boundary impurities selective dissolution theory

In production practice, we also learned that austenitic stainless steel in strong oxidizing media (such as concentrated nitric acid) can also produce intergranular corrosion, but the corrosion and in oxidizing or weakly oxidizing media in the case of different. Usually occurs in the solid solution treatment of steel, after the sensitization of steel generally does not occur. When the solid solution contains phosphorus impurities such as 100ppm or silicon impurities of 1000 – 2000ppm, they will be segregated on the grain boundaries. These impurities in the strong oxidizing medium under the action of dissolution, resulting in intergranular corrosion. While the steel is sensitized, because the carbon can be generated with phosphorus (MP) 23C6, or because the first carbon segregation limits the diffusion of phosphorus to the grain boundary, both of which will eliminate or reduce the impurities in the grain boundary segregation, eliminating or reducing the susceptibility of steel to intergranular corrosion.

The above two theories explaining the mechanism of intergranular corrosion are each applicable to a certain alloy organization state and a certain medium, not mutually exclusive but complementary to each other. Most of the most common intergranular corrosion of stainless steel in production practice is in weakly oxidizing or oxidizing media, and therefore the majority of corrosion cases can be explained by the chromium-poor theory.

3 intergranular corrosion caused by the media environment

Commonly used austenitic stainless steel intergranular corrosion caused by the media, there are two main categories. One is the oxidizing or weak oxidizing medium, one is a strong oxidizing medium, such as concentrated nitric acid. Common is the first category, the following list of common causes of austenitic stainless steel intergranular corrosion media environment.

- 1 Commonly caused by austenitic stainless steel intergranular corrosion media

In the “corrosion data chart” prepared by G. A. Nelson listed the common cause of austenitic stainless steel intergranular corrosion media: acetic acid, acetic acid + salicylic acid, ammonium nitrate, ammonium sulfate, chromic acid, copper sulfate, fatty acids, formic acid, ferric sulfate, hydrofluoric acid + ferric sulfate, lactic acid, nitric acid, nitric acid + hydrochloric acid, oxalic acid. phosphoric acid, seawater, salt spray, sodium bisulfate, sodium hypochlorite, sulfur dioxide (wet), sulfuric acid, sulfuric acid + copper sulfate, sulfuric acid + ferrous sulfate, sulfuric acid + methanol, sulfuric acid + nitric acid, sulfite, phthalic acid, sodium hydroxide + sodium sulfide.

- 2 Intergranular corrosion susceptibility test

Austenitic stainless steel used in the environment may cause intergranular corrosion, should be GB4334. 1 ~ GB4334 “stainless steel intergranular corrosion test method” for intergranular corrosion tendency test. Austenitic stainless steel intergranular corrosion tendency test method selection and its qualified requirements should be in accordance with the following provisions.

(1) in the temperature greater than or equal to 60 ℃, and the concentration of nitric acid greater than or equal to 5 % of the use of austenitic stainless steel and concentrated nitrate stainless steel, should be in accordance with GB4334. 3 “stainless steel 65% nitric acid corrosion test method” for the test, five cycles of the average corrosion rate or three cycles of corrosion rate should not be greater than 0. 6g/m2 h (or equivalent to 0. 6mm/a). Specimen state can be used or sensitized state.

(2) chromium-nickel austenitic stainless steel (such as 0Cr18Ni10Ti, 0Cr18Ni9, 00Cr19Ni10 and similar steel): general requirements: according to GB4334. 5 “stainless steel sulfuric acid – copper sulfate corrosion test method”, after the bending test, the surface of the specimen shall not have intergranular corrosion cracks. Higher requirements: according to GB4334. 2 “stainless steel sulfuric acid – iron sulfate corrosion test method”, the average corrosion rate should not be greater than 1. 1g/ m2 h.

(3) molybdenum-containing austenitic stainless steel (such as 0Cr18Ni12Mo2Ti, 00Cr17Ni14Mo2 and similar steel): general requirements: according to GB4334. 5 “stainless steel sulfuric acid – copper sulfate corrosion test method”, after the bending test, the sample surface shall not have intergranular corrosion cracks. Higher requirements: according to GB4334. 4 “stainless steel nitric acid – hydrofluoric acid corrosion test method”, the corrosion ratio of not more than 1. 5. can also be GB4334. 2 “sulfuric acid – iron sulfate test method”, the average corrosion rate should not be greater than 1. 1g/m2 h.

(4) the medium has special requirements, can be carried out outside the above provisions of the intergranular corrosion test, and the corresponding provisions of the qualified requirements.

4 prevent and control the intergranular corrosion measures

According to the corrosion mechanism, to prevent and control the austenitic stainless steel intergranular corrosion measures are as follows.

(1) the use of ultra-low carbon stainless steel to reduce the carbon content to 0. 03% below, such as the choice of 00Cr17Ni14Mo2, so that the steel does not form (Fe, Cr) 23C6, does not appear poor chromium area, to prevent intergranular corrosion. General strength is not high, the force is not large, the requirements of good plasticity parts, from an economic point of view, can choose 0Cr18Ni9 and so on.

(2) stabilized stainless steel selection of steel containing titanium and niobium stainless steel, (that is, we often say stabilized stainless steel), smelting steel by adding a certain amount of titanium and niobium two components, their affinity for carbon, so that the formation of TiC or NbC steel, and TiC or NbC solid solution degree than (Fe, Cr) 23C6 much smaller, in the solid solution temperature is almost insoluble in austenite. In this way, although after the sensitization temperature, (Fe, Cr) 23C6 does not cause a large number of precipitation at the grain boundaries, to a large extent to eliminate the austenitic stainless steel tendency to produce intergranular corrosion. Such as 1Cr18Ni9Ti, 1Cr18Ni9Nb and other steels, can work in the range of 500 to 700 ℃, there is no intergranular corrosion tendency.

(3) Re-solid solution treatment when welding austenitic stainless steel, the arc pool temperature up to 1300 ℃ or more, the temperature on both sides of the weld with the increase in distance and decline, where there is a sensitized temperature zone. Should try to avoid austenitic stainless steel in the sensitization temperature range of heat and slow cooling, if found to have a tendency to intergranular corrosion, generally for non-stabilized stainless steel heated to 1000 ~ 1120 ℃, holding temperature by 1 to 2 minutes per millimeter, and then rapid cooling; stabilized stainless steel to 950 ~ 1050 ℃ is appropriate. After solid solution treatment of steel still to prevent heating at the sensitization temperature, otherwise chromium carbide will precipitate again along the grain boundaries.

(4) choose the right welding method welding, if the operation is not skilled or welding material is too thick, the longer the welding time will stay in the sensitization temperature zone, the more opportunities, the result of the base material on both sides of the weld to produce sensitivity to intergranular corrosion. In order to reduce the sensitivity of the welded joint, welding should be minimized in the input of line energy. General argon arc welding than the arc welding input line energy is low, so welding and welding should be used argon arc welding. For the welded parts should be selected ultra-low carbon stainless steel or stainless steel containing Ti, Nb stabilizing elements, for the electrode should be selected ultra-low carbon electrodes or electrodes containing Nb. When using argon arc welding, in order to avoid overheating of the welded joint, the operation should be fast, after welding to quickly cool down, minimize the base material on both sides of the weld in the range of sensitization temperature stay time.

5 Post-weld treatment

Weld area does not necessarily emphasize post-weld heat treatment, general solution treatment to 1100 ~ 1150 ℃ range of holding time after a certain period of acute cooling, three minutes to complete the cooling of 925 ~ 540 ℃ temperature range, in the continued fast cooling to 425 ℃ or less; stabilization treatment to 850 ~ 880 ℃ temperature range after a few hours of holding air cooling. The expected post-weld heat treatment effect, with the heat treatment process of each key process parameters (such as furnace temperature, heating speed, heating process temperature difference between parts of the workpiece, furnace atmosphere, holding time, holding process temperature difference between parts, cooling speed, furnace temperature, etc.) is closely linked.

For austenitic stainless steel containers that may cause intergranular corrosion environment, the general parts of the solid solution treatment or stabilization treatment can be achieved. The whole vessel (mostly heat exchangers) weld post-weld heat treatment will face a lot of difficulties. This type of treatment is not a local post-weld heat treatment, but the entire welded parts or the whole vessel post-weld heat treatment. Due to the complex shape of the structure of most chemical vessels (such as our commonly used shell and tube heat exchangers).

If the requirement for the whole shell and tube heat exchanger weld area post-weld solution or stabilization treatment, the above key process parameters are simply not controlled, let alone to ensure the quality of post-weld heat treatment. Even if the treatment is often botched, not only the weld structure has not been improved, but the parent material structure has been unduly deteriorated. Therefore, even for the intergranular corrosion environment of austenitic stainless steel chemical vessels, more than 90 % is still welded state use, rather than post-weld heat treatment state use.

6 A little view

Chromium-nickel austenitic stainless steel is the most commonly used corrosion-resistant materials, and intergranular corrosion is the most common form of failure of chromium-nickel austenitic stainless steel containers. Intergranular corrosion greatly weakened the intergranular bond, and in severe cases, the mechanical strength can be completely lost. Suffering from this corrosion of stainless steel, the surface seems to be very bright, but can not withstand a light knock will break into fine grains. As intergranular corrosion is not easy to check, so, resulting in the sudden destruction of equipment, it is very harmful, should cause us to pay sufficient attention.

Chromium-nickel austenitic stainless steel containers are basically formed by welding, and welded joints on both sides of the intergranular corrosion sensitization area, it is always more than the parent material first by corrosion damage. Through post-weld heat treatment, improve the weld area resistance to intergranular corrosion, and the base material to the same extent, which is the goal we pursue, is our original intention of post-weld heat treatment. However, in practice, there are many factors to consider, such as: the overall structure of the weld shape is complex, post-weld heat treatment process parameters are difficult to ensure, therefore, in fact, the vast majority of in-service chromium-nickel austenitic stainless steel in the post-weld state use.

For intergranular corrosion resistance of chromium-nickel austenitic stainless steel container weld area whether for solution treatment or stabilization treatment, can not simply generalize, should be specific analysis of the structure of the container shape, analysis can guarantee the effect of heat treatment, otherwise even if we put forward the requirements of post-weld heat treatment, but often contrary to expectations, not only does not achieve the desired effect, but will affect the structure of the base material.

In order to improve the ability of chromium-nickel austenitic stainless steel container resistance to intergranular corrosion, must be for the specific corrosive environment, according to the corrosion mechanism, the first selection of materials optional ultra-low carbon stainless steel, stainless steel stabilization, welding, the use of the correct welding method, the appropriate combination of the above several preventive and control measures, in order to achieve good results, can not simply rely on post-weld solution or stabilization treatment.

Wilson Pipeline is a leading manufacturer and distributor of flange fittings material from alloy steel stainless steel to carbon steel.products, including Super Duplex Stainless Steel Flanges, Stainless Steel Flanges, Stainless Steel Pipe Fittings. ASME B16.5 ASME B16.9 ASME B16.11 EN1092,ANSI ASTM,GOST,JIS,DINWilson Pipeline products are widely used in Shipbuilding, Nuclear power, Marine engineering, Petroleum, Chemical, Mining, Sewage treatment, Natural gas and Pressure vessels and other industries.If you want to have more information you want to share your enquiry with us, contact us at sales@wilsonpipeline.com