1.Barrel body and skirt seat using support

The support is mainly used to prevent the deformation of the barrel of large oversized equipment after the barrel is rolled, welded and rounded, and to play the deformation prevention support (including one type, cross type and meter type) at the edge of the barrel section and inside. The support also applies to the site manufacturing needs to be sent to the site from the manufacturing plant in sections, in the process of transportation to the site to prevent deformation by playing the support. In the process of lifting and transferring, in order to prevent the deformation of the cylinder due to its own self-weight plus the traction force of the spreader, it is necessary to play the support. In the process of forming the barrel sections, due to the large diameter of the barrel and the thin outer wall of the vessel, when the barrel sections are placed on the roller frame, the barrel is deformed by the rotation of the roller frame plus the self-weight of the barrel, and the straightness cannot be guaranteed in the process of welding forming, and this process also needs to be supported inside the barrel, as shown in the figure below.

2. Barrel opening using support

For large thin-walled vessels, often need to open a large number of receiver holes in the barrel, especially the tower production process is complex, the installation of more internal parts, receiver also more, the barrel needs to open a large number of receiver holes, and the equipment itself is larger in diameter, the wall thickness is thin, in the cutter gas cutting holes at the same time there has been a small deformation, after opening the hole to assemble the receiver, due to the weight of the receiver itself, in the receiver and barrel Welding at the same time, the local temperature at the opening on the barrel is too high to carry the weight of the receiver, resulting in the collapse of the receiver at the opening of the barrel, the internal sink, affecting the installation size. In this case, it is necessary to put support at the edge of the receiver opening to prevent deformation during the opening and assembly of the receiver, as shown in the figure below.

Circumferential preheating of thick-walled cylinders

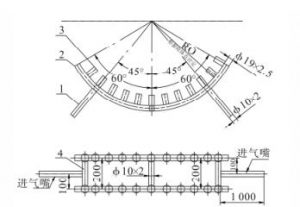

For thick-walled pressure vessels in order to ensure the welding performance, the welding bevels need to be preheated before welding, the bevels reach a certain temperature before welding, as well as in the welding process need to keep warm while welding, the role of preheating tooling will be very important, if the preheating effect is not good or not preheating will lead to substandard weld quality or even brittle steel will lead to weld around the blowout. For the thick-walled cylinder in order to prevent the welding process cracks, the cylinder is preheated before the base welding, after a long period of practice, according to the actual needs of the production of the cylinder weld preheating tooling, as shown in the following figure.

Pressure vessel preheating tooling includes: inlet pipe, heating pipe, burner, connecting pipe, and bracket. The above components are welded together, and the bracket is adjusted according to the height of the preheated part, when using, firstly, the heating tube is bent according to the size of the cylinder diameter, the heating tube is closed at both ends, and holes are drilled on the part connected to the burner to deliver natural gas to the burner, the distance between the burner and the outer surface of the cylinder is 20~30 mm, the whole assembly determines the preheating range and the height of the assembly bracket according to the width of the weld seam and the cylinder diameter, and the preheating range of the weld seam is determined. In order to increase the preheating range and heating speed, holes are opened on both sides of the middle of the burner, and finally all the parts are welded together, and the whole tooling is welded and fixed directly below the weld preheating area. . If the workload is large, more than one heating tube can be manufactured at a time and used at the same time to improve production efficiency.

Card transfer, flip

In the manufacture of pressure vessels, cylinder lifting, transferring and turning is an essential procedure. Previously used cylinder transfer, turning tooling generally by the wire rope or ordinary card using the crane directly through the hook connected to the wire rope or card lifting, for the weight of the cylinder section, the wire rope to bear the load is limited, fatigue, wear degree is not determined, the wire rope lifting capacity can not be judged, may lead to the wire rope beyond the scope of the load, the wire rope broken cylinder slip; In addition, the card to the cylinder of the card The strength is not enough, may lead to the cylinder slide down, causing safety accidents, also not good protection.

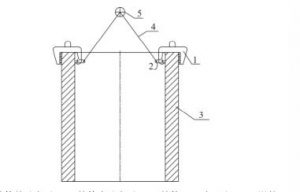

A feasible tooling is shown below, 1 and 2 are connected by bolts, and the spreader A and B are connected by wire rope and dynamic pulley, and the serrated table is welded on the inner surface of 1 and 2, and the height of the serrated table is 3~5 mm, which is to increase the friction between 1 and 2 and the inner and outer wall of the cylinder.

The lifting force is transferred through the pulley and the wire rope by connecting the pulley and the wire rope via the overhead crane to increase the clamping force of the clamps on the inner wall of the barrel. The said die is used in conjunction with the spreader to be stuck on the cylinder wall for lifting and turning.

Tower plate support ring installation, inspection

The installation of the tower support ring is essential in the manufacture of pressure vessels, and the installation accuracy directly determines whether the equipment can be put into normal production. Before the tower support ring and the installation of internal parts are riveter master by the overall scribing, and then each piece and then scribe to determine the installation position, due to human operation, the error is large, low efficiency, precision is not high, and time-consuming, labor-intensive.

As shown in the figure below, the tower support ring installation accuracy positioning, adjustable tooling use, first measure the installed tower support ring and the size of the inner parts, according to the size of the tower support ring and inner parts first determine the length of 1 and 2. If the equipment diameter is small, the required tower support ring and the size of the inner parts of the specification is also small, you can directly use 1 and 2 for scribing installation. If the equipment diameter is larger, you can drill holes on 2 to connect 3 for installation, so that its installation accuracy to meet the drawings and technical requirements. In case of pressure vessel reducer equipment, multiple dies 1 and 2 of the same size can be made at the same time, and only the size of die 3 can be changed for the scribing and installation of another equipment to improve production efficiency.

Picture

Overall straightness check of the equipment

Straightness is a must during and after the manufacturing of pressure vessels. Improper straightness control after pressure vessel production will result in the equipment may not be put into use. And for the pressure vessel specification is large, using other equipment inspection is not convenient, manual measurement accuracy is not high, so the use of a whole tooling will achieve efficient and fast inspection.

Said tower overall straightness inspection tooling, its structure includes: a pair of angles, a fine steel wire, several fine wire plus pendant; equal length angles welded to the upper and lower head center receiver, fine wire fixed in the same position of the two angles. The length of a pair of angles must be the same and the edge of the angles in the center of the receiver, fine wire fixed in the same position on the angles and taut, will be several fine wire from the same orientation of the cylinder natural hanging, check the distance between the fine wire and fine wire to determine whether the straightness is reasonable, as shown in the figure below.

Wilson Pipeline is a leading manufacturer and distributor of flange fittings material from alloy steel stainless steel to carbon steel.products, including Super Duplex Stainless Steel Flanges, Stainless Steel Flanges, Stainless Steel Pipe Fittings. ASME B16.5 ASME B16.9 ASME B16.11 EN1092,ANSI ASTM,GOST,JIS,DINWilson Pipeline products are widely used in Shipbuilding, Nuclear power, Marine engineering, Petroleum, Chemical, Mining, Sewage treatment, Natural gas and Pressure vessels and other industries.If you want to have more information you want to share your enquiry with us, contact us at sales@wilsonpipeline.com