Specifications

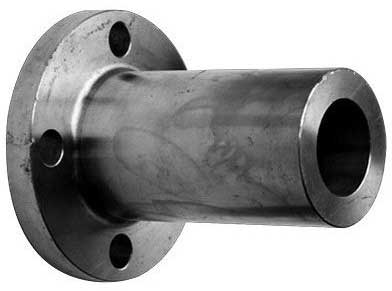

ASME B16.5 ASTM A182 F53 LWNRF Flange 1 Inch CL300

1. Material: 2507 (UNS S32750/F53), etc

2. Size: 1 Inch

3. Standard: ANSI, ASME, etc

4. Pressure: 300#

F53 LWN Flanges is used for high pressure situations, LWN Flanges are used and for very high pressure cases Long Welding Neck flanges are preferred. In this case, the weld are far from the ring to avoid bending stresses and weld stress being combined.

China Flange Manufacturer supplies ASME B16.5 ASTM A182 F53 LWNRF Flange, 1 Inch, CL300.

Chemical Composition Of F53 UNS 32750 GR2507 Super Duplex Stainless Steel

|

GRADE

|

C≤

|

Mn≤

|

Si≤

|

S≤

|

P≤

|

Cr≤

|

Ni

|

Mo

|

Cu≤

|

N

|

|

S32750

(2507)

00Cr25Ni7Mo4N

|

0.03

|

1.20

|

0.8

|

0.020

|

0.035

|

24.0/26.0

|

6.0/8.0

|

3.0/5.0

|

0.50

|

0.24/0.32

|

| Type | F53 LWNRF Flange |

| Size | 1 Inch |

| Standards | WNRF, SO, WN, SW, TH, LJ, BL, PL, LWNRF, etc |

| Material | Stainless Steel: ASTM A403 WP304, 304L, 310, 316, 316L, 321, 347, 904L

Carbon Steel: ASTM A234 WPB, WPC ASTM A105 WPHY 42, 46, 52, 56, 60, 65, 70 Alloy Steel: ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91 Duplex Stainless Steel: F51, 2205, F53, 2507, etc |

| Surface treatment | Chamfering |

| Applications | Petroleum,chemical,power,gas,metallurgy, shipbuilding, construction, etc |

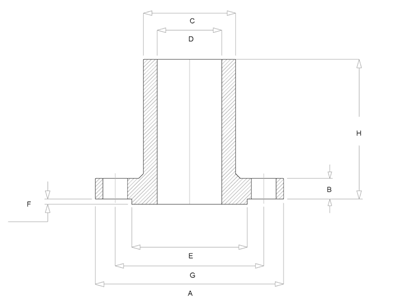

Long Weld Neck Flange Dimensions Class 300

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Weld Neck OD | RF Dia. | RF Height | PCD | Hub Length | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size |

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 95 | 12.7 | 38 | 21.3 | 34.9 | 2 | 66.7 | As Required | 4 | 1/2 | 55 | 65 | 5/8 | M14 |

| 3/4 | 20 | 115 | 14.3 | 48 | 26.7 | 42.9 | 2 | 82.6 | As Required | 4 | 5/8 | 65 | 75 | 3/4 | M16 |

| 1 | 25 | 125 | 15.9 | 54 | 33.4 | 50.8 | 2 | 88.9 | As Required | 4 | 5/8 | 65 | 75 | 3/4 | M16 |

| 1 1/4 | 32 | 135 | 17.5 | 64 | 42.2 | 63.5 | 2 | 98.4 | As Required | 4 | 5/8 | 70 | 85 | 3/4 | M16 |

| 1 1/2 | 40 | 155 | 19.1 | 70 | 48.3 | 73 | 2 | 114.3 | As Required | 4 | 3/4 | 75 | 90 | 7/8 | M20 |

| 2 | 50 | 165 | 20.7 | 84 | 60.3 | 92.1 | 2 | 127 | As Required | 8 | 5/8 | 75 | 90 | 3/4 | M16 |

| 2 1/2 | 65 | 190 | 23.9 | 100 | 73 | 104.8 | 2 | 149.2 | As Required | 8 | 3/4 | 85 | 100 | 7/8 | M20 |

| 3 | 80 | 210 | 27 | 117 | 88.9 | 127 | 2 | 168.3 | As Required | 8 | 3/4 | 90 | 110 | 7/8 | M20 |

| 3 1/2 | 90 | 230 | 28.6 | 133 | 101.6 | 139.7 | 2 | 184.2 | As Required | 8 | 3/4 | 95 | 110 | 7/8 | M20 |

| 4 | 100 | 255 | 30.2 | 146 | 114.3 | 157.2 | 2 | 200 | As Required | 8 | 3/4 | 95 | 115 | 7/8 | M20 |

| 5 | 125 | 280 | 33.4 | 178 | 141.3 | 185.7 | 2 | 235 | As Required | 8 | 3/4 | 110 | 120 | 7/8 | M20 |

| 6 | 150 | 320 | 35 | 206 | 168.3 | 215.9 | 2 | 269.9 | As Required | 12 | 3/4 | 110 | 120 | 7/8 | M20 |

| 8 | 200 | 380 | 39.7 | 260 | 219.1 | 269.9 | 2 | 330.2 | As Required | 12 | 7/8 | 120 | 140 | 1 | M24 |

| 10 | 250 | 445 | 46.1 | 321 | 273 | 323.8 | 2 | 387.4 | As Required | 16 | 1 | 140 | 160 | 1 1/8 | M27 |

| 12 | 300 | 520 | 49.3 | 375 | 323.8 | 381 | 2 | 450.8 | As Required | 16 | 1 1/8 | 145 | 170 | 1 1/4 | M30 |

| 14 | 350 | 585 | 52.4 | 425 | 355.6 | 412.8 | 2 | 514.4 | As Required | 20 | 1 1/8 | 160 | 180 | 1 1/4 | M30 |

| 16 | 400 | 650 | 55.6 | 483 | 406.4 | 469.9 | 2 | 571.5 | As Required | 20 | 1 1/4 | 165 | 190 | 1 3/8 | M33 |

| 18 | 450 | 710 | 58.8 | 533 | 457 | 533.4 | 2 | 628.6 | As Required | 24 | 1 1/4 | 170 | 195 | 1 3/8 | M33 |

| 20 | 500 | 775 | 62 | 587 | 508 | 584.2 | 2 | 685.8 | As Required | 24 | 1 1/4 | 185 | 205 | 1 3/8 | M33 |

| 24 | 600 | 915 | 68.3 | 702 | 610 | 692.2 | 2 | 812.8 | As Required | 24 | 1 1/2 | 205 | 230 | 1 5/8 | M39 |

Special Flanges

What are special flanges..

Special Flanges are basically identical to standard flanges, but have a number of special features.

Long Welding Neck flange

Long Neck Welding (abbreviated LWN) flanges are similar to a standard Welding Neck flange, but the “Neck” is considerably longer. This type is often used as a nozzle for a barrel or column. In addition, there are the type LWN Heavy Barrel (HB) and the Equal LWN Barrel (E); they have a different shape and a thicker “Wall”.

Weldoflange / Nipoflange

The Weldoflange and Nipoflange is a combination of a Welding Neck flange and a supposedly Weldolet or Nipolet. The 2 components are manufactured in one piece, and not welded. These flanges are primarily in Branchconnections.

you can find more information about the various performances, dimensions etc.. Furthermore, they have an expanded range of special flanges, fittings and branch connections.

Expander flange

Expander Flanges is a Welding Neck pipe flange where the nominal size of the non-flanged end is larger than the nominal size of the flanged end. They can be used to change the size of a pipe run. These are usually used to increase the line size to the first or second larger size. This is an alternative to using a separate reducer and weld neck flange combination. The expander flange can be used to connect pipe to pumps, compressors and Valves.

Reducing flange

Reducing Flanges are suitable for changing line size, but should not be used if abrupt transition would create undesirable turbulence, as at pump connections. A reducing flange consists of a flange with one specified diameter having a bore of a different and smaller, diameter. Except for the bore and hub dimensions, the flange will have dimensions of the larger pipe size.

APPLICATIONS Of F53 LWNRF Flange:

1. Petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry