Dimensions Slip On Flanges & Stud Bolts ASME B16.5

| CLass | 150 | 300 | 600 | 900 | 1500 | 2500 |

| DIA A |

30 | 38 | 38 | 38 | 38 | … |

| DIA D |

90 | 95 | 95 | 120 | 120 | … |

| THK B |

9.6 | 12.7 | 14.3 | 22.3 | 22.3 | … |

| 11.2 | 14.3 | 20.7 | 28.7 | 28.7 | … | |

| DIA G |

35.1 | 35.1 | 35.1 | 35.1 | 35.1 | … |

| DIA K |

60.3 | 66.7 | 66.7 | 82.6 | 82.6 | … |

| H | 14 | 21 | 22 | 32 | 32 | … |

| 15.6 | 22.6 | 28.4 | 38.4 | 38.4 | … | |

| NO. L |

4 | 4 | 4 | 4 | 4 | … |

| DIA L |

15.9 | 15.9 | 15.9 | 22.2 | 22.2 | … |

| Stud Bolts Diameter x Length | ||||||

| DIA (in) |

1/2 | 1/2 | 1/2 | 3/4 | 3/4 | … |

| Len mm |

55 | 65 | 75 | 110 | 110 | … |

| Other Diameters | |||||||

| NPS | 1/2 | 3/4 | 1 | 1.1/4 | 1.1/2 | 2 | 2.1/2 |

| 3 | 3.1/2 | 4 | 6 | 8 | 10 | 12 | |

| 14 | 16 | 18 | 20 | 24 | |||

Notes..

- Dimensions are in millimeters unless otherwise indicated.

- The length of the Stud Bolt does not include the height of the chamfers (points).

Composition ranges for 304L grade stainless steel

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

|

|

304 |

min. max. |

– 0.08 |

– 2.0 |

– 0.75 |

– 0.045 |

– 0.030 |

18.0 20.0 |

– |

8.0 10.5 |

– 0.10 |

|

304L |

min. max. |

– 0.030 |

– 2.0 |

– 0.75 |

– 0.045 |

– 0.030 |

18.0 20.0 |

– |

8.0 12.0 |

– 0.10 |

|

304H |

min. max. |

0.04 0.10 |

– 2.0 |

– 0.75 |

-0.045 |

– 0.030 |

18.0 20.0 |

– |

8.0 10.5 |

– |

Mechanical properties of 304L grade stainless steel

|

Grade |

Tensile Strength (MPa) min |

Yield Strength 0.2% Proof (MPa) min |

Elongation (% in 50mm) min |

Hardness |

|

|

Rockwell B (HR B) max |

Brinell (HB) max |

||||

|

304 |

515 |

205 |

40 |

92 |

201 |

|

304L |

485 |

170 |

40 |

92 |

201 |

|

304H |

515 |

205 |

40 |

92 |

201 |

|

304H also has a requirement for a grain size of ASTM No 7 or coarser. |

|||||

Physical properties of 304L grade stainless steel in the annealed condition

|

Grade |

Density (kg/m3) |

Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion (μm/m/°C) |

Thermal Conductivity (W/m.K) |

Specific Heat 0-100°C (J/kg.K) |

Electrical Resistivity (nΩ.m) |

|||

|

0-100°C |

0-315°C |

0-538°C |

at 100°C |

at 500°C |

|||||

|

304/L/H |

8000 |

193 |

17.2 |

17.8 |

18.4 |

16.2 |

21.5 |

500 |

720 |

Grade specifications for 304L grade stainless steel

|

Grade |

UNS No |

Old British |

Euronorm |

Swedish SS |

Japanese JIS |

||

|

BS |

En |

No |

Name |

||||

|

304 |

S30400 |

304S31 |

58E |

1.4301 |

X5CrNi18-10 |

2332 |

SUS 304 |

|

304L |

S30403 |

304S11 |

– |

1.4306 |

X2CrNi19-11 |

2352 |

SUS 304L |

|

304H |

S30409 |

304S51 |

– |

1.4948 |

X6CrNi18-11 |

– |

– |

|

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted. |

|||||||

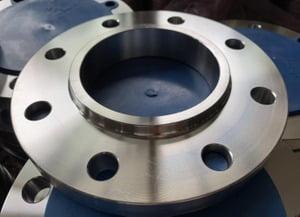

| Type | SORF Flange |

| Size | 1/2″ to 120″ |

| Standards | SO, WN, SW, TH, LJ, BL, PL, etc |

| Material | Stainless Steel: ASTM A403 WP304, 304L, 310, 316, 316L, 321, 347, 904L

Carbon Steel: ASTM A234 WPB, WPC ASTM A105 WPHY 42, 46, 52, 56, 60, 65, 70 Alloy Steel: ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91 Duplex Stainless Steel: F51, 2205, F53, 2507, etc |

| Sealing surface | FF, RF, LJ, FM, R.T.J, R.J and so on |

| Applications | Petroleum,chemical,power,gas,metallurgy, shipbuilding, construction, etc |

Studs are measured parallel to the axis (L) from

the first to the thread without the chamfers (points)

S = free threads equals 1/3 time bolt dia

Hex bolts are measured from under the head to the top of de bolt

Dimensional Tolerances of Slip On Flanges ASME B16.5

Tolerances not listed in ASME B16.5 2013

≤ 24 = 1.6 mm

> 24 = ± 3.2 mm

≤ 10 = ± 0.8 mm

≥ 12 = + 1.6 mm / – 0 mm

≤ 12 = + 2.4 mm / – 1.6 mm

≥ 14 = ± 3.2 mm

Same as for Inside Diameter

Bolt Circle = 1.6 mm

Bolt Hole Spacing = ± 0.8 mm

≤ 2.1/2 = 0.8 mm max.

≥ 3 = 1.6 mm max.

≤ 18 = + 3.2 mm / – 0

≥ 20 = + 4.8 mm / – 0

≤ 18 = + 3.2 mm / – 0.8 mm

≥ 20 = + 4.8 mm / – 1.6 mm

1.6 mm Raised Face = ± 0.8 mm

6.35 mm Raised Face, Tongue and Groove / Male-Female = ± 0.4 mm