Specifications

ASME B16.36 ALLOY 31 Orifice Flange Welding Neck Raised Face

1. Material: Alloy 31 (Alloy 1.4562 / UNS N08031)

2. Size: 6″ (DN150)

WT: Sch10S

3. Standard: ASME, etc

4. Pressure: 300#

China Orifice Flange Manufacturer Yaang offers ASME B16.36 ALLOY 31 Orifice Flange Welding Neck Raised Face, 6 Inch, SCH10S, CL300.

Alloy 31 is a nickel, chromium and molybdenum stainless steel with nitrogen and cupper additions. It combines moderate tensile strength and high ductility with excellent corrosion resistance in sulfuric acid, reducing and oxidizing media and has strong resistance to corrosion and erosion corrosion in phosphoric environment.

Typically the alloy has PREN of ≥ 48, which ensure that the resistance to pitting corrosion is high.

Chemical composition of Alloy 31

| Alloy 31, N08031, 1.4562, | ||

| Chemical composition(%) | Carbon, max | 0.015 |

| Manganese, max | 2.0 | |

| Phosphorus, max | 0.020 | |

| Sulfur, max | 0.010 | |

| Silicon, max | 0.3 | |

| Nickel | 30.0~32.0 | |

| Chromium | 26.0~28.0 | |

| Molybdenum | 6.0~7.0 | |

| Copper | 1.0~1.4 | |

| Nitrogen | 0.15~0.25 | |

| Iron | balance | |

| Tensile strength(MPa, min) | 650 | |

| 0.2% Yield strength(MPa, min) | 276 | |

| Elongation(%, min) | 40 | |

| Type | ALLOY 31 Orifice Flange |

| Size | 6″ (DN150) WT: Sch10S |

| Standard or Nonstandard | Standard |

| Material | Stainless Steel: ASTM A403 WP304, 304L, 310, 316, 316L, 321, 347, 904L

Carbon Steel: ASTM A234 WPB, WPC ASTM A105 WPHY 42, 46, 52, 56, 60, 65, 70 Alloy Steel: ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91 Duplex Stainless Steel: F51, 2205, F53, 2507, etc |

| Surface treatment | Chamfering |

| Applications | Petroleum,chemical,power,gas,metallurgy, shipbuilding, construction, etc |

An Orifice Flange is used in combination with orifice meters to measure the flow rate of oil, gas and other liquids conveyed by the pipeline. Orifice flanges are manufactured to ASME B16.36 in multiple sizes and, material grades.

An orifice flange is used to measure the flow of the fluid conveyed by the pipeline via a flow nozzle positioned on the flange itself. Pairs of pressure tappings are machined onto the orifice flange, making separate tappings on the pipe wall unnecessary.

The traditional orifice flange assembly consists of a pair of flanges, orifice plate, bolts, nuts, gaskets, jacking screws and plugs. Jacking screws ensure the easy removal of the primary flow element.

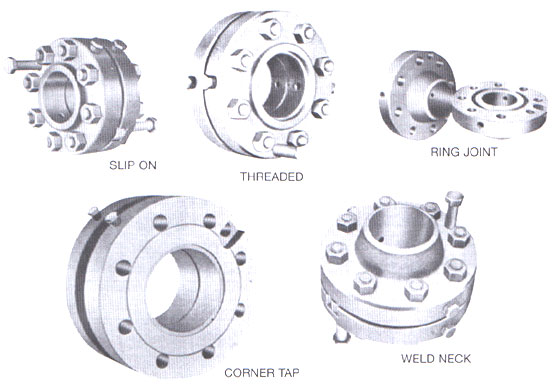

Orifice flanges are available in all ASTM forged grades (ASTM A105, ASTM A350, ASTM A694, ASTM 182 respectively for carbon, alloy and, stainless steel flanges), dimensions (combinations of nominal sizes and pressure ratings) and, in socket weld, threaded or weld neck shape (WN is the most used).

The range of orifice flanges covers all standard sizes and ranges, and all common flange materials. Flanges are available in Welding Neck, Slip On, and Threaded form, and are typically supplied with two 1/2″ NPT tappings in each flange.

ASME B16.36 covers Dimensions and dimensional tolerances from orifice flanges (similar to those covered in ASME B16.5) that have orifice pressure differential connections. Coverage is limited to the following flanges:

- WELDING NECK CLASSES 300, 400, 600, 900, 1500, 2500

- SLIP ON CLASS 300

- THREADED CLASS 300

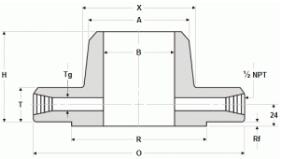

ORIFICE FLANGE DIMENSIONS (WELD NECK, CLASS 300 RF)

| NPS | A | R | O | T | H | X | Tg |

| 1 | 33.4 | 50.8 | 125 | 36.6 | 81 | 54 | 6.4 |

| 1½ | 48.3 | 73 | 155 | 36.6 | 84 | 70 | 6.4 |

| 2 | 60.3 | 92.1 | 165 | 36.6 | 84 | 84 | 6.4 |

| 2½ | 73 | 104.8 | 190 | 36.6 | 87 | 100 | 6.4 |

| 3 | 88.9 | 127 | 210 | 36.6 | 87 | 117 | 9.5 |

| 4 | 114.3 | 157.2 | 255 | 36.6 | 90 | 146 | 12.7 |

| 6 | 168.3 | 215.9 | 320 | 36.6 | 98 | 206 | 12.7 |

| 8 | 219.1 | 269.9 | 380 | 39.7 | 110 | 260 | 12.7 |

| 10 | 273 | 323.8 | 445 | 46.1 | 116 | 321 | 12.7 |

| 12 | 323.8 | 381 | 520 | 49.3 | 129 | 375 | 12.7 |

| 14 | 355.6 | 412.8 | 585 | 52.4 | 141 | 425 | 12.7 |

| 16 | 406.4 | 469.9 | 650 | 55.6 | 144 | 483 | 12.7 |

| 18 | 457 | 533.4 | 710 | 58.8 | 157 | 533 | 12.7 |

| 20 | 508 | 584.2 | 775 | 62 | 160 | 587 | 12.7 |

| 24 | 610 | 692.2 | 915 | 68.3 | 167 | 702 | 12.7 |

| NPS | Bolt Diameter | # Bolts | Bolt holes diameter | Bolts Diameter | Bolts lenght mm. |

| 1 | 88.9 | 4 | 11/16 | 5/8 | 125 |

| 1½ | 114.3 | 4 | 13/16 | 3/4 | 135 |

| 2 | 127 | 8 | 11/16 | 5/8 | 125 |

| 2½ | 149.2 | 8 | 13/16 | 3/4 | 135 |

| 3 | 168.3 | 8 | 13/16 | 3/4 | 135 |

| 4 | 200 | 8 | 13/16 | 3/4 | 135 |

| 6 | 269.9 | 12 | 7/8 | 3/4 | 135 |

| 8 | 330.2 | 12 | 1 | 7/8 | 145 |

| 10 | 387.4 | 16 | 1 1/8 | 1 | 165 |

| 12 | 450.8 | 16 | 1¼ | 1 1/8 | 180 |

| 14 | 514.4 | 20 | 1¼ | 1 1/8 | 185 |

| 16 | 571.5 | 20 | 1 3/8 | 1¼ | 195 |

| 18 | 628.6 | 24 | 1 3/8 | 1¼ | 205 |

| 20 | 685.8 | 24 | 1 3/8 | 1¼ | 215 |

| 24 | 812.8 | 24 | 1 3/8 | 1½ | 240 |

COMMENTS: Height of Raised Face (RF) in CLASS 300 is 2 mm

APPLICATIONS:

1. Petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

Where can we find the high quality ASME B16.36 ALLOY 31 Orifice Flange Welding Neck Raised Face, 6 Inch, SCH10S, CL300.