ASTM A403 TP304L STUB END 314-015

Size: 2″ (DN50)

Thk: Sch25H

Material: 304L

China STUB END Manufacturer wilson pipeline offers ASTM A403 TP304L STUB END 314-015, DN50, Sch25H.

Composition ranges for 304 grade stainless steel

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

|

|

304 |

min. max. |

– 0.08 |

– 2.0 |

– 0.75 |

– 0.045 |

– 0.030 |

18.0 20.0 |

– |

8.0 10.5 |

– 0.10 |

|

304L |

min. max. |

– 0.030 |

– 2.0 |

– 0.75 |

– 0.045 |

– 0.030 |

18.0 20.0 |

– |

8.0 12.0 |

– 0.10 |

|

304H |

min. max. |

0.04 0.10 |

– 2.0 |

– 0.75 |

-0.045 |

– 0.030 |

18.0 20.0 |

– |

8.0 10.5 |

– |

Mechanical properties of 304 grade stainless steel

|

Grade |

Tensile Strength (MPa) min |

Yield Strength 0.2% Proof (MPa) min |

Elongation (% in 50mm) min |

Hardness |

|

|

Rockwell B (HR B) max |

Brinell (HB) max |

||||

|

304 |

515 |

205 |

40 |

92 |

201 |

|

304L |

485 |

170 |

40 |

92 |

201 |

|

304H |

515 |

205 |

40 |

92 |

201 |

|

304H also has a requirement for a grain size of ASTM No 7 or coarser. |

|||||

Physical properties of 304 grade stainless steel in the annealed condition

|

Grade |

Density (kg/m3) |

Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion (μm/m/°C) |

Thermal Conductivity (W/m.K) |

Specific Heat 0-100°C (J/kg.K) |

Electrical Resistivity (nΩ.m) |

|||

|

0-100°C |

0-315°C |

0-538°C |

at 100°C |

at 500°C |

|||||

|

304/L/H |

8000 |

193 |

17.2 |

17.8 |

18.4 |

16.2 |

21.5 |

500 |

720 |

Grade specifications for 304 grade stainless steel

|

Grade |

UNS No |

Old British |

Euronorm |

Swedish SS |

Japanese JIS |

||

|

BS |

En |

No |

Name |

||||

|

304 |

S30400 |

304S31 |

58E |

1.4301 |

X5CrNi18-10 |

2332 |

SUS 304 |

|

304L |

S30403 |

304S11 |

– |

1.4306 |

X2CrNi19-11 |

2352 |

SUS 304L |

|

304H |

S30409 |

304S51 |

– |

1.4948 |

X6CrNi18-11 |

– |

– |

|

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted. |

|||||||

|

Type |

304L Stub End |

|

Standard |

ASME B16.9, MSS SP-43, HG205099, HG20621, GB/T12459-2005, GB/T13401, SH3408-96,etc. |

|

Size |

1/2″-48″(DN15-DN600) |

|

Wall thickness |

SCH5S-SCH40S |

|

Type |

Type A, Type B,Type C |

|

Surface treatment |

Lathe finish&Abrasive blasting |

|

Stainless steel |

304, 304L,304H, 316, 316L,309S,310S, 321,321H,347H,316Ti |

|

Duplex steel |

2205, etc |

|

Super duplex steel |

2507, etc |

WP304L Stub End

What are they?

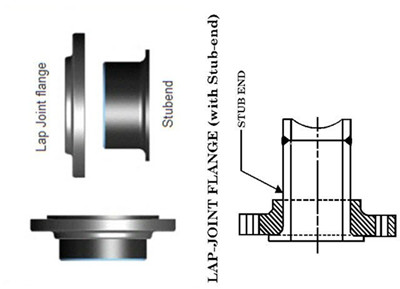

WP304L Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired.

They are also called Lap Joints and Vanstone Flared Laps.

How do they work?

A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Why?

Since Stub Ends are made from material compatible with the designed piping system, back up flanges do not have to be made from the same material. The flange can be made from less expensive material because it never comes in contact with the process fluid.

WP304L Stub Ends’ Types

WP304L Stub Ends are typically manufactured by two methods. Type A & B Stub Ends are made similar to forged fittings such as Elbows and Flanges. Type C Stub Ends are made by forming pipe to the desired dimensions.

WP304L Stub Ends are available in two standard lengths, MSS and ANSI.

WP304L Stub Ends are normally provided with a standard weld bevel

WP304L Stub Ends dimensions are found on our fitting dimensions page.

Type “A” – Type “B” – Type “C” – Type “CS”

Where can we find the high quality ASTM A403 TP304L STUB END 314-015 DN50 Sch25H.

Dimensions butt welded Stub Ends schedule 10S MSS SP-43 type A/B

| NPS | OD | T | G | F | R Type A |

R Type B |

| 1/2 | 21.3 | 2.11 | 34.9 | 50.8 | 3.05 | 0.76 |

| 3/4 | 26.7 | 2.11 | 42.9 | 50.8 | 3.05 | 0.76 |

| 1 | 33.4 | 2.77 | 50.8 | 50.8 | 3.05 | 0.76 |

| 1.1/4 | 42.2 | 2.77 | 63.5 | 50.8 | 4.83 | 0.76 |

| 1.1/2 | 48.3 | 2.77 | 73 | 50.8 | 6.35 | 0.76 |

| 2 | 60.3 | 2.77 | 92.1 | 63.5 | 7.87 | 0.76 |

| 2.1/2 | 73 | 3.05 | 104.8 | 63.5 | 7.87 | 0.76 |

| 3 | 88.9 | 3.05 | 127 | 63.5 | 9.65 | 0.76 |

| 3.1/2 | 101.6 | 3.05 | 139.7 | 76.2 | 9.65 | 0.76 |

| NPS | OD | T | G | F | R Type A |

R Type B |

| 4 | 114.3 | 3.05 | 157.2 | 76.2 | 11.18 | 0.76 |

| 5 | 141.3 | 3.40 | 185.7 | 76.2 | 11.18 | 1.52 |

| 6 | 168.3 | 3.40 | 215.9 | 88.9 | 12.7 | 1.52 |

| 8 | 219.1 | 3.76 | 269.9 | 101.6 | 12.7 | 1.52 |

| 10 | 273.1 | 4.19 | 323.9 | 127 | 12.7 | 1.52 |

| 12 | 323.9 | 4.57 | 381 | 152.4 | 12.7 | 1.52 |

| 14 | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 1.52 |

| 16 | 406.4 | 4.78 | 469.9 | 152.4 | 12.7 | 1.52 |

| 18 | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 1.52 |

| 20 | 508 | 5.54 | 584.2 | 152.4 | 12.70 | 1.52 |

| 24 | 609.6 | 6.35 | 692.2 | 152.4 | 12.7 | 1.52 |

Dimensions are in millimeters unless otherwise indicated. Weights are in kilograms and approximately given.

Dimensional Tolerances of Stub Ends MSS SP-43

| Nominal Pipe Size | 1/2 up to 2.1/2 | 3 to 3.1/2 | 4 | 5 to 8 | 10 to 18 | 20 to 24 |

| Outside Diameter at Welding End (OD) | 0.8 | 0.8 | 0.8 | + 1.6 – 0.8 |

+ 2.29 – 0.76 |

+ 3.05 – 0.76 |

| Overall Length (F) | 1.6 | 1.6 | 1.6 | 1.6 | 2 | 2 |

| Outside Diameter of Lap (G) | + 0 – 0.76 |

+ 0 – 0.76 |

+ 0 – 0.76 |

+ 0 – 0.76 |

+ 0 – 1.6 |

+ 0 – 1.6 |

| Thickness of Lap (T) | + 1.52 – 0 |

+ 1.52 – 0 |

+ 1.52 – 0 |

+ 1.52 – 0 |

+ 1.52 – 0 |

+ 1.52 – 0 |

| Fillet Radius of Lap (R) | + 0 – 0.76 |

+ 0 – 0.76 |

+ 0 – 1.6 |

+ 0 – 1.6 |

+ 0 – 1.6 |

+ 0 – 1.6 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||||

Dimensional tolerances are in millimeters unless otherwise indicated.

Notes..

- Type A for Lap Joint Flanges

- Type B for Slip On Flanges

- MSS SP-43 only covers stainless steel buttweld fittings made for use with Schedule 5S and 10S pipe and Stub Ends suitable for use with Schedule 40S pipe, as defined in ASME B36.19. The dimensions and dimensional tolerances defined in MSS SP-43 are substantially the same as those in ASME B16.9 specifications from NPS 1/2 – NPS 24. Except with regard to the outside diameter at the bevel.