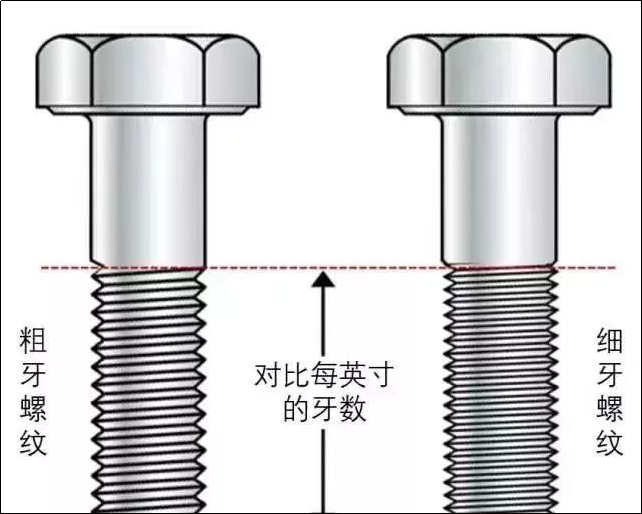

How fine a thread can be called a fine thread? We may define it this way. Coarse threads can be defined as standard threads, while fine threads are relative to coarse threads, with different numbers of teeth per inch in the same nominal diameter, i.e. different pitches, with coarse threads having larger pitches and fine threads having smaller pitches.

That is to say, for both 1/2-13 and 1/2-20 specifications, the former is coarse teeth while the latter is fine teeth. Therefore, it is expressed as 1/2-13UNC and 1/2-20UNF.

Since there are two different thread sizes for the same nominal diameter, how do you choose between coarse and fine threads?

Coarse thread

Coarse threads are actually standard threads, and we usually buy stainless steel screws and other fasteners with coarse threads without special instructions.

Coarse threads are characterized by high strength, good interchangeability, and the availability of standards, so generally speaking, coarse threads should be the best choice.

Compared with fine threads, the thread pitch is large and the thread lift angle is also large, so the self-locking property is poor, and it is necessary to install anti-loosening washers and self-locking devices in the vibration environment.

Coarse threads do not need to be marked with pitch, such as M8, M12-6H, M16-7H, etc., and are mainly used as coupling threads.

Fine threads

Fine threads are the opposite of coarse threads, and are specified to supplement the special use requirements that coarse threads cannot meet. Fine threads also have a pitch series, and the pitch of fine threads is smaller, so they are characterized by being more conducive to self-locking, anti-loosening, and more teeth, which can reduce the role of leakage and achieve the effect of sealing. In some precision occasions, fine tooth stainless steel screws are more convenient for precise control and adjustment.

The disadvantage is that the tensile value, strength is lower than coarse teeth, and the thread is easy to damage, it is not recommended to disassemble for many times, with the matching nuts and other fasteners may be equally accurate, a slight error in size, easy to make the screws and nuts damaged at the same time.

Fine threads are mainly used in metric fittings of hydraulic systems, mechanical transmission parts, thin-walled parts with insufficient strength, in-machine parts restricted by space and shafts with high requirements for self-locking, etc. Fine threads must be marked with pitch to show the difference from coarse threads.

How to choose coarse and fine threads

Both coarse thread and fine thread screws are used for fastening purposes.

Fine thread screws are generally used for locking thin-walled parts and parts with high requirements for vibration prevention. Fine threads have good self-locking properties and are therefore resistant to vibration and loosening, but because of the shallow thread depth, they are less able to withstand greater tension than coarse threads.

When no anti-loosening measures are taken, fine threads are more effective than coarse threads, and are generally used for thin-walled parts and parts with high vibration resistance requirements.

When used for adjustment, fine threads have more advantages. Disadvantage of fine thread: It is not suitable for the application on the material with excessively coarse organization and poor strength, and when the tightening force is large, it is easy to slip the thread.

Wilson Pipeline is a leading manufacturer and distributor of flange fittings material from alloy steel stainless steel to carbon steel.products, including Super Duplex Stainless Steel Flanges, Stainless Steel Flanges, Stainless Steel Pipe Fittings. ASME B16.5 ASME B16.9 ASME B16.11 EN1092,ANSI ASTM,GOST,JIS,DINWilson Pipeline products are widely used in Shipbuilding, Nuclear power, Marine engineering, Petroleum, Chemical, Mining, Sewage treatment, Natural gas and Pressure vessels and other industries.If you want to have more information you want to share your enquiry with us, contact us at sales@wilsonpipeline.com