A, the development status of acoustic emission technology

In the mid-1970s, the acoustic emission testing of pressure vessels was carried out by the Institute of Mechanical Research, and in the 1980s, the China Special Equipment Testing and Research Center conducted a more in-depth study on the acoustic emission testing of pressure vessels and assessment methods, and carried out research on the acoustic emission characteristics of composite pressure vessels and testing applications. Into the 1990s to the present, acoustic emission technology in China’s research and application of the rapid development trend. So far, many technical supervision system boiler and pressure vessel inspection institute purchased multi-channel acoustic emission instrument to carry out pressure vessel inspection work. 2003 August General Administration of Quality Supervision, Inspection and Quarantine promulgated the inspection agency management regulations will be acoustic emission testing technology as one of the common non-destructive testing methods for pressure vessel inspection, and set up a professional non-destructive testing company can engage in pressure vessel acoustic emission testing work. Since then, the acoustic emission testing of pressure vessels has been formally incorporated into China’s special equipment safety supervision and regulation system and formally recognized by the government.

Second, the nature of acoustic emission technology

Acoustic emission concept.

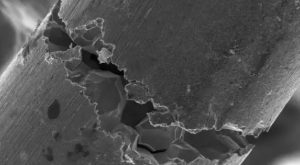

When the stress reaches the plastic domain, the frequency of acoustic emission will increase rapidly, and then gradually decrease after reaching the maximum value. When a crack occurs in the boiler vessel to be inspected, a concentrated stress is generated at the top of the crack, causing this part to enter the plastic domain earlier than the rest of the vessel, resulting in acoustic emission. A crack of several millimeters should be created in the boiler vessel beforehand and then tested in extension. Four types of cracks were cut and the longest cracked boiler vessel fractured under minimum load. This shows that the object fractures at a fraction of the ultimate load because of the influence of the cracks. The amplitude of the acoustic emission produced at this time increases and will be interrupted as the crack expands.

Third, the detection method of acoustic emission technology

Usual non-destructive conventional testing methods are generally only for static detection, and the most dangerous hidden danger in the boiler pressure vessel is usually the development of defects, acoustic emission detection is in the metal material under the action of stress deformation plastic and expansion of defects, the generation of physical phenomena of acoustic signals. The signal is acquired and analyzed using transducers multi-channel simultaneously using electronic modern processing technology, which in turn obtains information about dynamic defects in the loaded parts. Using acoustic emission monitoring equipment, dynamic defects in the material structure are located and detected. This provides a review of the structural integrity. The acoustic emission technique differs from other probing methods, which must be scanned one by one in the vicinity of the defective part, relying mainly on a few fixed and unchanging sensors for a more complete determination of the entire device. The most significant advantage of this method is that online inspection can be performed at any time.

In fact, most boiler pressure vessel accidents are caused by defects. Effective inspection of welding defects and assessment of defects in a certain degree on the vessel pressure detection. The normal method of detecting vessel pressure is welding nondestructive comprehensive testing and flaw detection ultrasonic, etc.. In general, internal welding flaw detection can not be less than 20% of the internal X-ray seam, and sometimes even 100% of its nondestructive testing, and fracture mechanics assessment of the defective parts of the weld, this work often requires a large amount of work and requires a long detection time. Acoustic emission technology detection signal is issued by the transducer’s multi-channel on the pressure of the parts generated by the internal deformation of the material defects when the deformation phenomenon, and these signals are collected and organized, and finally obtain the signal generated by the defect parameters. For example, the amplitude of the stress, the number or number of times and the location of the stress defect, the stress defect load, etc., and ultimately to assess the purpose of defects. Because acoustic emission technology can implement a comprehensive quantitative positioning of welding defects, while acoustic emission detection is faster and less capital, acoustic emission has developed into one of the important means of pressure vessel defect detection.

Acoustic emission detection technology is often carried out simultaneously with the pressure vessel hydrostatic test process, so as to identify areas where developmental welding defects are likely to occur. The first step of the inspection takes approximately the same amount of time as the hydrostatic test. The data from the test results are stored on a computer hard drive, and the location of the emission source is predicted on the vessel shell surface. Because acoustic emission testing uses a computer to control automatic defect data collection, the data are more reliable, there is less interference caused by human factors, and the data can be stored for a long time.

The results show excellent performance in locating the identified acoustic emission sources. In China, acoustic emission inspection technology is widely used in the inspection of pressure vessels. Some research institutions of acoustic emission technology will be the introduction of emission technology, digestion, absorption, research and application, the ultimate goal is to adopt high-tech, the amount of labor of pressure vessel field inspection to improve, faster and better service to the majority of users. Acoustic emission actively reflects information on internal defects of materials under loaded conditions without using a probe to scan on the measured surface, which changes the traditional NDT method of passive detection into active detection. In terms of inspection scope, acoustic emission is an all-round inspection, and the location and direction of defects do not affect the detection rate of defects by acoustic emission. Acoustic emission is a dyna mic non-destructive test, which is combined with stress and can determine the severity of the defect under the influence of stress.

Fourth, the detection mechanism of acoustic emission technology

Understanding the acoustic emission source characteristics of the site pressure vessel is the basis for the analysis and interpretation of pressure vessel acoustic emission signal source, through a comprehensive analysis of acoustic emission inspection data, as well as the discovery of acoustic emission source of conventional non-destructive testing re-inspection results, the site pressure vessel acoustic emission inspection may encounter typical acoustic emission source is divided into seven categories, the following describes the parts and mechanisms of these sources of acoustic emission.

Pressure vessel weld surface cracks and internal deep buried cracks on the tip of the plastic deformation blunting and expansion and acoustic emission signal. Pressure vessel weld within the existence of porosity, slag, fusion and penetration of defects such as cracking and expansion and fracture of non-metallic slag materials can produce acoustic emission signal. The collision of the vessel external scaffolding, internal tower plate, external insulation and platform support components can produce mechanical friction acoustic emission signal.

In addition, the vertical container skirt seat and horizontal container saddle-type support are connected by the pad plate container shell and support plate, general pad plate and container shell using all or part of the fillet weld welding. In the pressurization process, the pad and shell expansion inconsistency caused by friction can produce a large number of acoustic emission signal. For new pressure vessel. The first pressurized easy to appear such signals; for the pressure vessel in use, weld repair parts easy to appear such acoustic emission sources.

In addition, the container skirt, support, pillar and receiver and other fillet weld parts easy to produce welding residual stress and stress concentration. In the process of pressure boosting stress redistribution can produce a large number of acoustic emission signal. In the air pressure or water pressure test process on the vessel receiver, flange, manhole and defective penetration parts of the leak, can produce a large number of acoustic emission signal. Long-term use of steel pressure vessels, both inside and outside are prone to oxidation. Sometimes the internal medium is corrosive, the external environment is humid, acid rain and sea breeze, etc. can produce more serious corrosion, in the process of hydrostatic testing, the rupture of these oxidation skin peeling process will produce a large number of acoustic emission signal.

V. Development trend

Now the use of pressure vessels in the design, manufacture, inspection and use and other aspects of strict management, has rarely found more serious defects, so in the case of ensuring the safe operation of pressure vessels, how to extend the operating cycle of pressure vessels, and minimize the time of inspection, is the most important concern of the majority of pressure vessel users. Because of the advantages of acoustic emission technology, acoustic emission detection technology has a huge application market in online monitoring of in-service pressure vessels. As the pressure vessel operating online in most cases can not be found for the acoustic emission source of conventional non-destructive testing methods to re-test. Therefore, the identification of the nature of the pressure vessel acoustic emission source and the determination of the degree of risk research and improvement is bound to be the development direction of pressure vessel acoustic emission inspection technology.

Six, concluding remarks

Acoustic emission testing is a new technology of nondestructive testing, as a major method of periodic inspection of pressure vessels in service is very effective and fully feasible. This technology can meet the operating condition of the equipment, timely detection of equipment, timely detection of potential accidents, into the possible reduction of equipment accident risk. We should vigorously promote this high-tech, so that acoustic emission detection of this method is more widely used in our inspection work. Improve the level of inspection, testing and efficiency to ensure the safety and normal operation of the equipment.